High impact strength + high heat resistance

Engineering Material for 3D Printing

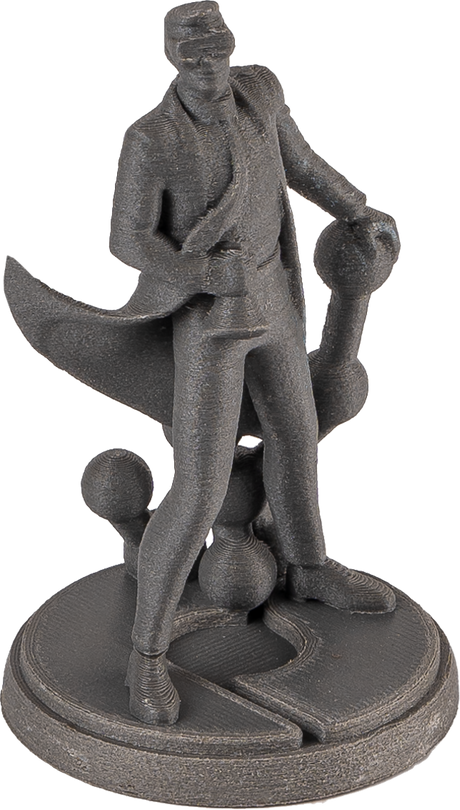

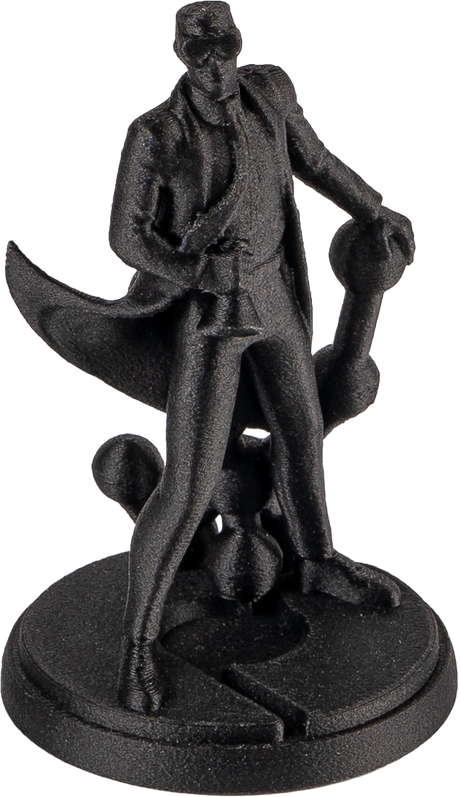

PA - which stands for polyamide nylon - is a very strong 3D printing material option.

Nylon

View allNylon FAQ

Are there any printing requirements?

Are there any printing requirements?

The only requirements would be to make sure your hotend can reach the recommended temperature range, and then you also will need a hardened nozzle when printing in a carbon fiber or glass fiber reinforced option.

You do not need any enclosure when you print with our nylon options.

You will want to use a filament dryer - like the PolyDryer - the entire time you print.

What is difference between PA6, PA612, and PA12?

What is difference between PA6, PA612, and PA12?

PA6 (Nylon 6) and PA12 (Nylon 12) are both polyamide plastics, but they differ in their chemical structure, properties, and applications.

Key Differences:

Moisture Absorption: PA12 has a lower moisture absorption rate compared to PA6, which makes it more suitable for applications where humidity is a concern. PA12 reaches moisture equilibrium at a lower percentage than PA6.

Mechanical Properties: Both materials have similar tensile strength and stiffness, but PA12 exhibits better resistance to water-induced changes in mechanical properties. This means that PA12’s mechanical properties remain more consistent in wet conditions.

PA612 will be in-between the two in mechanical properties, resistance to moisture, and even price.

What is annealing and why is it needed?

What is annealing and why is it needed?

Our nylon filaments come with our Warp-Free™ technology. This Warp-Free™ technology solves one root of the cause of warping - crystallization.

Indeed, Nylon is known as challenging to print because of its warping behavior, because when printing, the quick formation of crystals within each layers will create a lot of internal stress - resulting in part deformation.

Polymaker’s technology is not only reducing this stress, but it is increasing the mechanical properties of the part. The technology slows down the crystallization rate of the polymer, which prevents it from quickly forming small crystals within each layer as they are printed. Instead, it allows the polymer to slowly build big crystal across layers, since multiple layers have time to be printed before the formation of crystals. These crystals across the layers will also significantly increase the inter layer adhesion. This is also the reason why Polymaker will recommend to anneal the part after the printing process. Annealing ensures the part has reached its highest degree of crystallinity, providing the best thermal and mechanical properties.

This means you are not on a time crunch with our nylon materials to get them in the oven the moment the print finishes, as we recommend with polycarbonate which you will read about shortly. You can get the print into the oven at your convenience - just know after you anneal in the oven, the nylon will be dried out and will slowly moisture condition after.

Each nylon will have slightly different annealing recommendations, but we generally recommend between 80˚-100˚C for 6-16 hours. This will allow the nylon to fully crystallize.

Why do you use such a low build plate temperature with your nylons?

Why do you use such a low build plate temperature with your nylons?

Our nylons come with our Warp-Free™ Technology.

Polymaker’s technology is not only reducing this stress, but it is increasing the mechanical properties of the part. The technology slows down the crystallization rate of the polymer, which prevents it from quickly forming small crystals within each layer as they are printed. Instead, it allows the polymer to slowly build big crystal across layers, since multiple layers have time to be printed before the formation of crystals. These crystals across the layers will also significantly increase the inter layer adhesion. This is also the reason why Polymaker will recommend to anneal the part after the printing process. Annealing ensures the part has reached its highest degree of crystallinity, providing the best thermal and mechanical properties.

In order for this Warp-Free™ technology to work as it should - we want to make sure the build plate and the ambient air temperatures are both below 50˚C. We then anneal the print after to get it's full strength.

What is moisture conditioning?

What is moisture conditioning?

Nylons are very hygroscopic - meaning they absorb moisture very easily.

This means that your finished nylon print will absorb moisture - there is no real way around this. This means your part may grow very slightly and have different mechanical properties after being moisture conditioned.

PA12-CF was developed to be less susceptible to this moisture.

To moisture condition - you can leave your nylon part in a high humidity environment for 48 hours, or just leave it out for 2 weeks as it naturally absorbs the moisture in the air.

Should I anneal before or after moisture conditioning?

Should I anneal before or after moisture conditioning?

When you anneal in a convection oven, you will dry the part out. So if you moisture condition before annealing - you will need to moisture condition again after. So we would suggest to moisture condition after annealing.

Will the spools work in an AMS?

Will the spools work in an AMS?

Yes! We have redesigned the edges of our spools so all Polymaker products will now spin great in the AMS.

That said - you will need to be careful when using any abrasive materials in the AMS.

I want a strong nylon - what do you suggest?

I want a strong nylon - what do you suggest?

This can depend on what you define as "Strong". If you want impact resistant - the best option would be PA6-CF or PA6-GF.

That said - PA6 is more susceptible to moisture and therefore will have more dimensional and property changes than PA12 or PA612.

Where are all the docs? TDS, SDS, etc.?

Where are all the docs? TDS, SDS, etc.?

You can view all material products' TDS, SDS, and Printing Profiles HERE

You can then find that information for Fiberon Nylon materials HERE

You can also find mechanical properties HERE

You can then find our other docs:

Need further information? We would recommend joining our Discord. Thousands of active community members may have already created the profile you are looking for!

Canada

Canada Global

Global