What is the difference between active foaming and passive foaming?

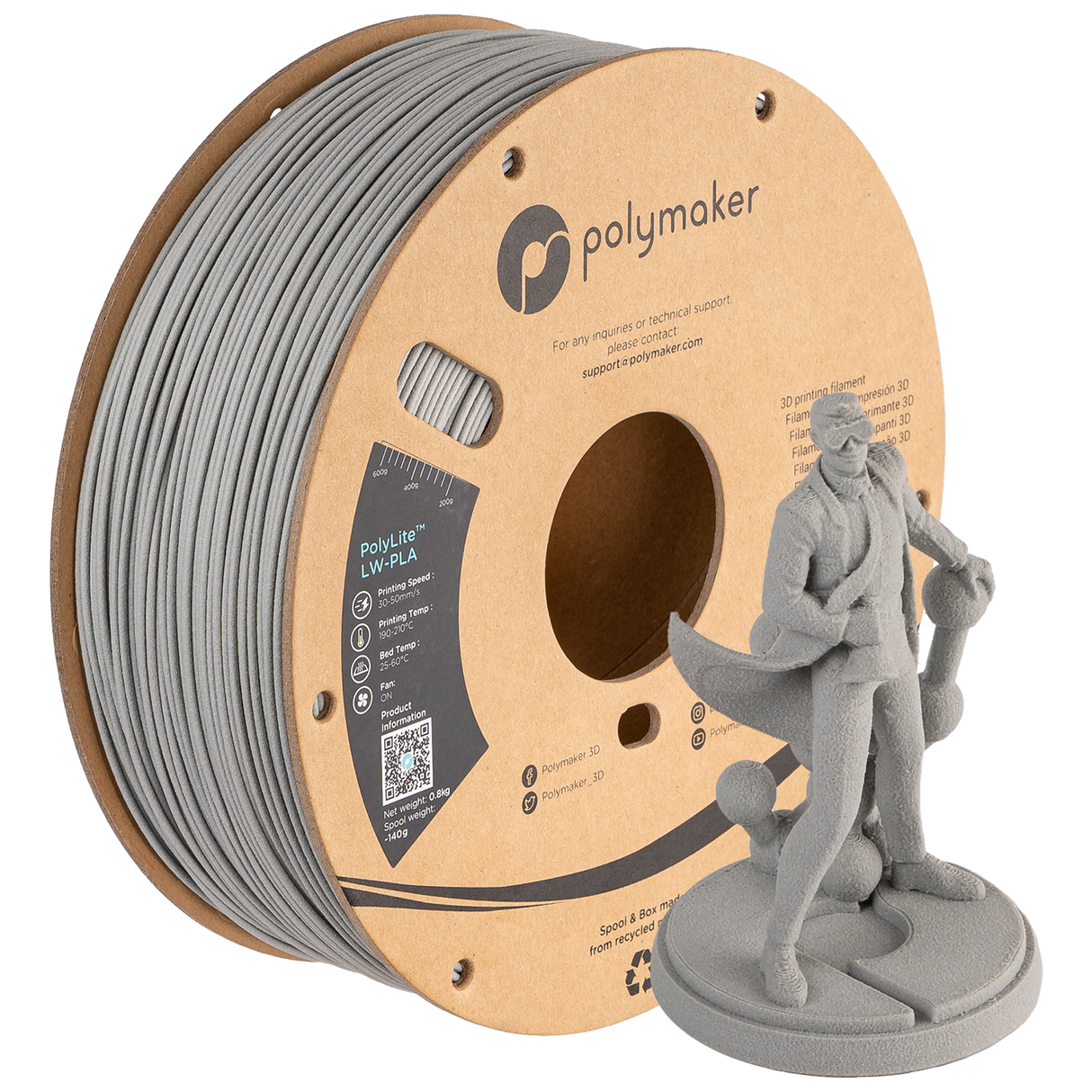

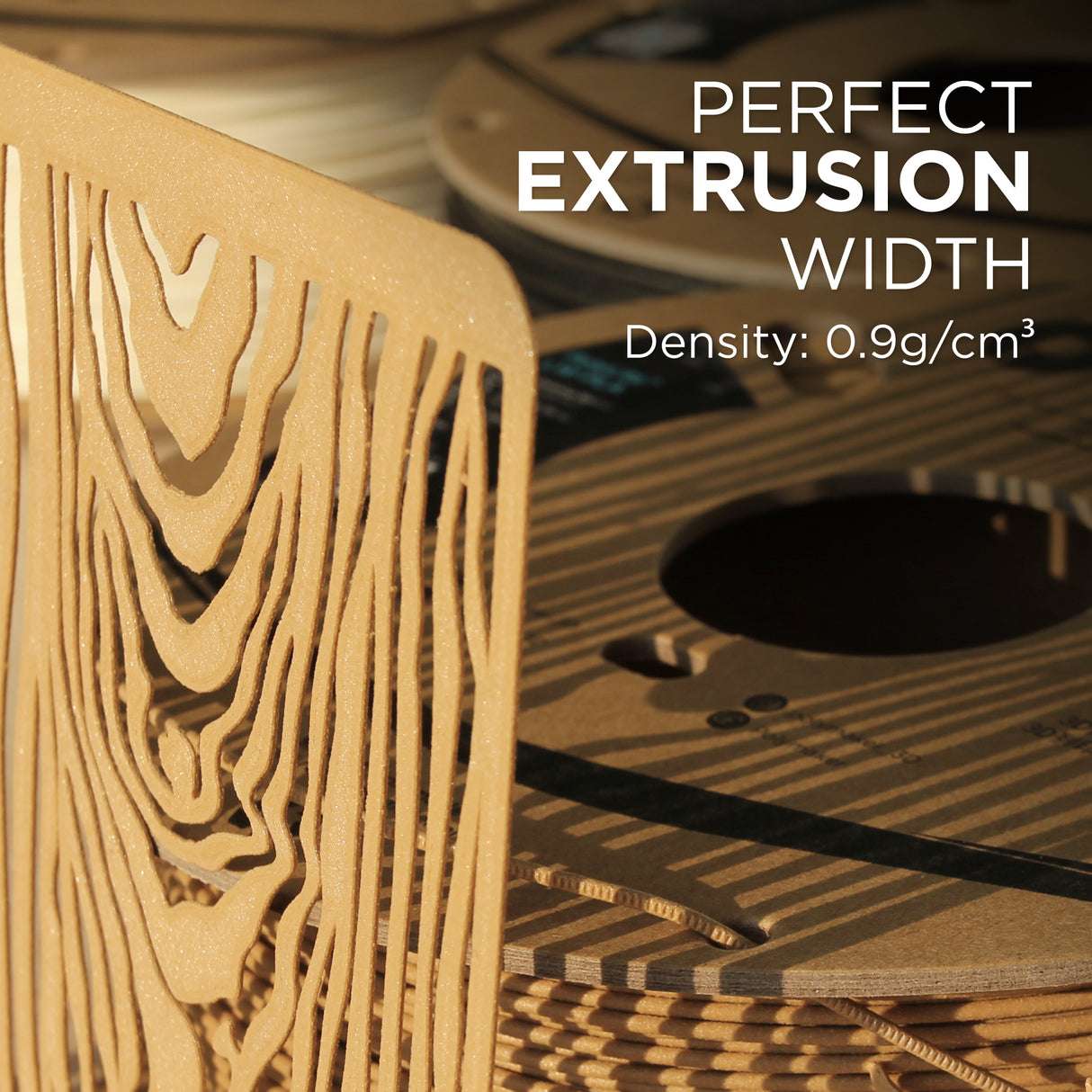

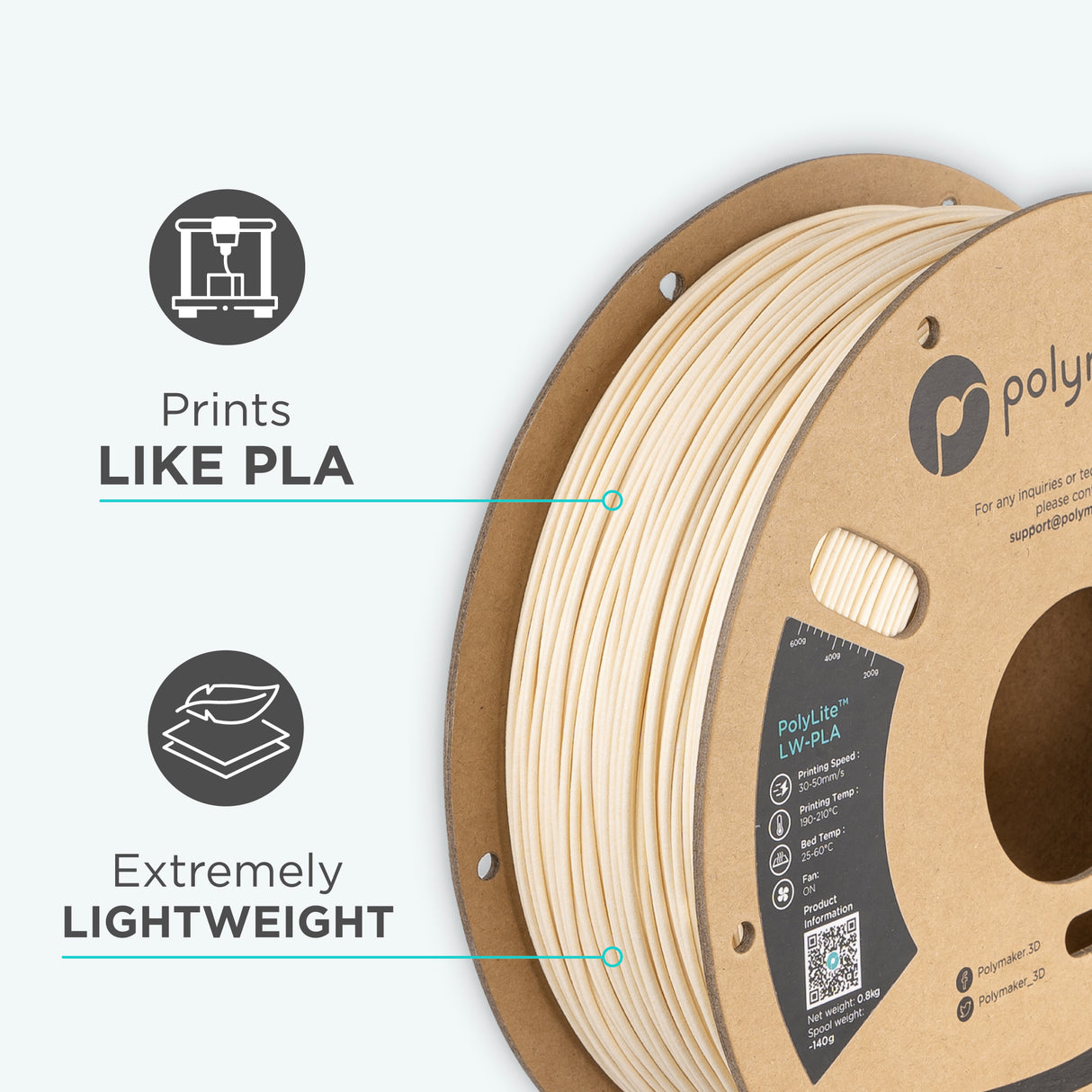

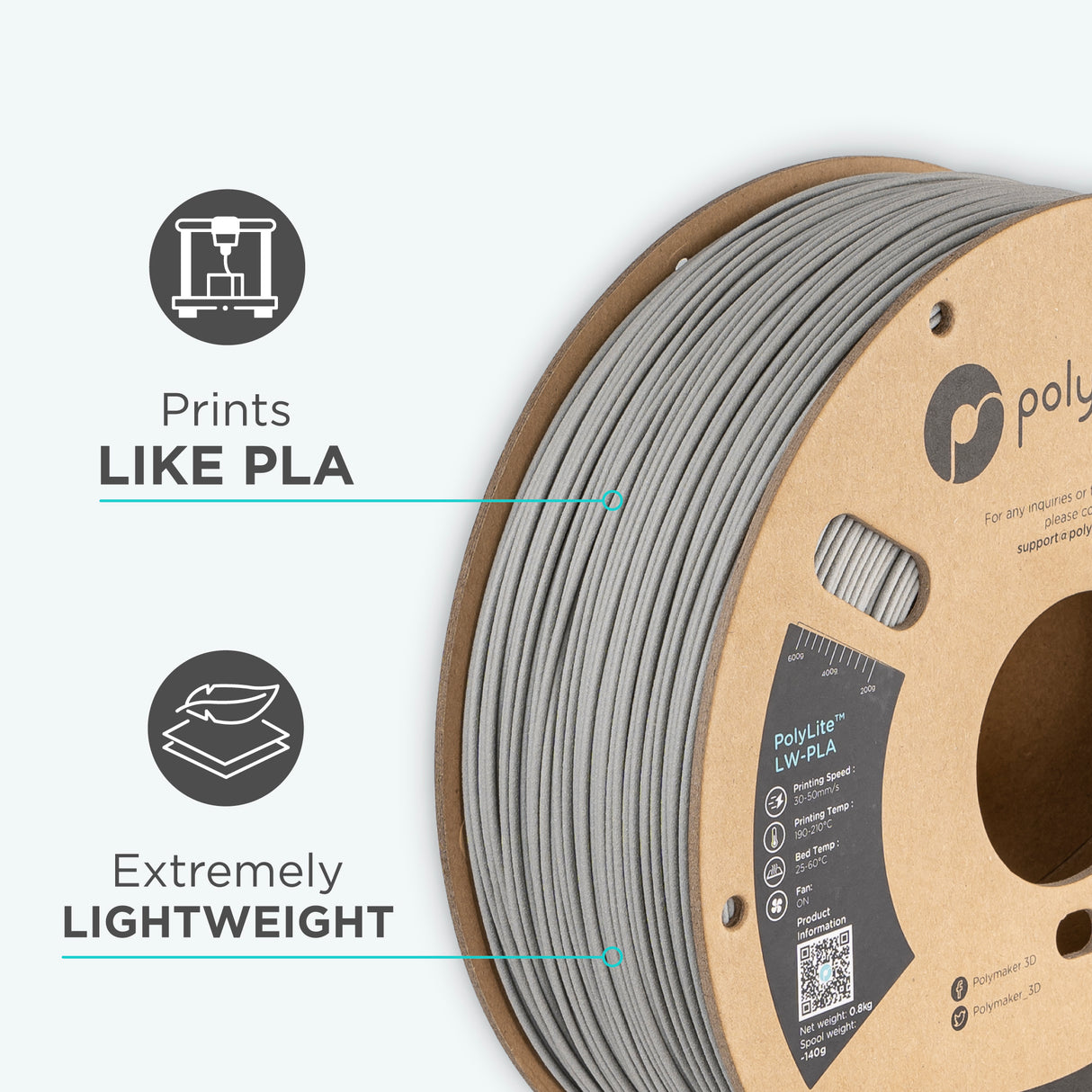

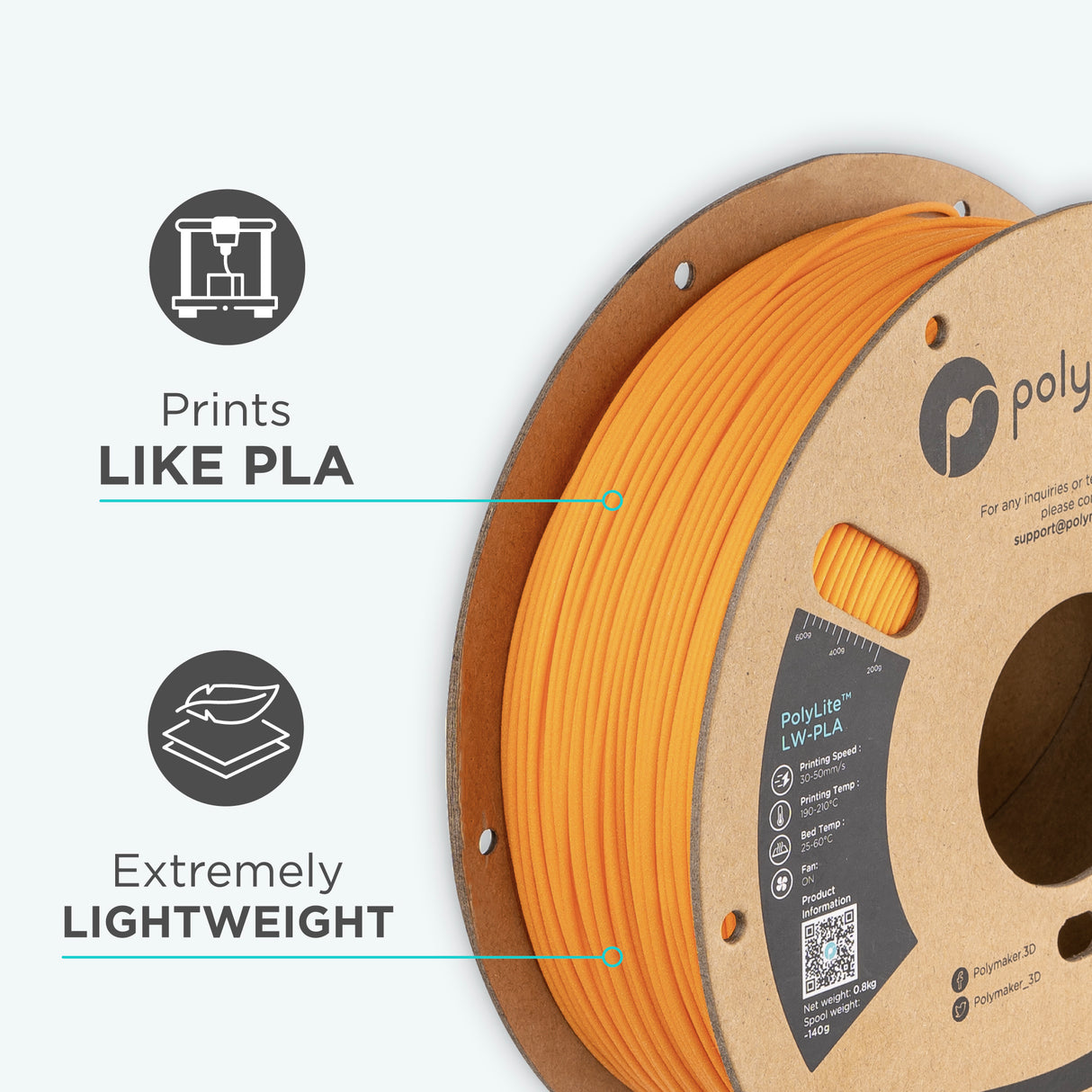

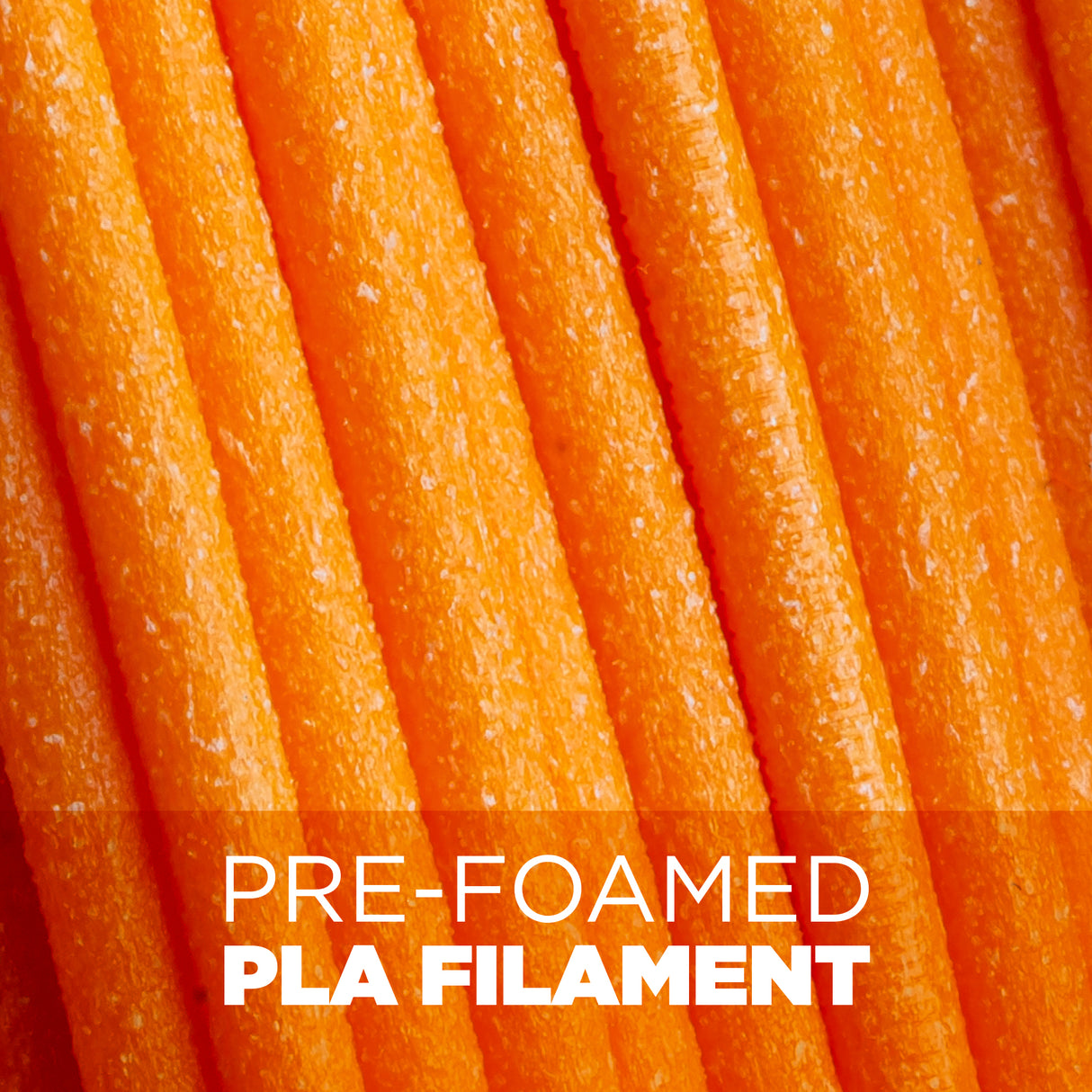

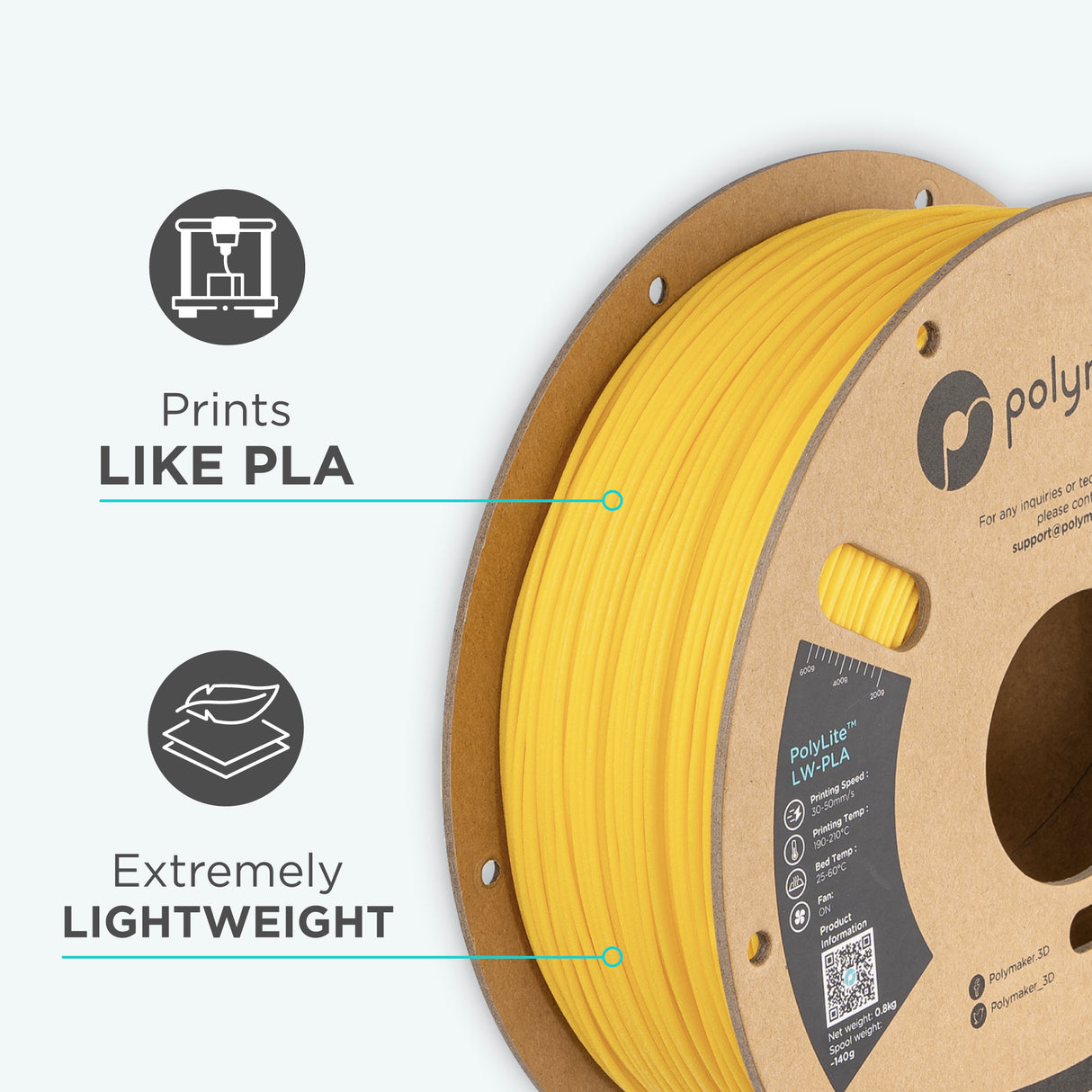

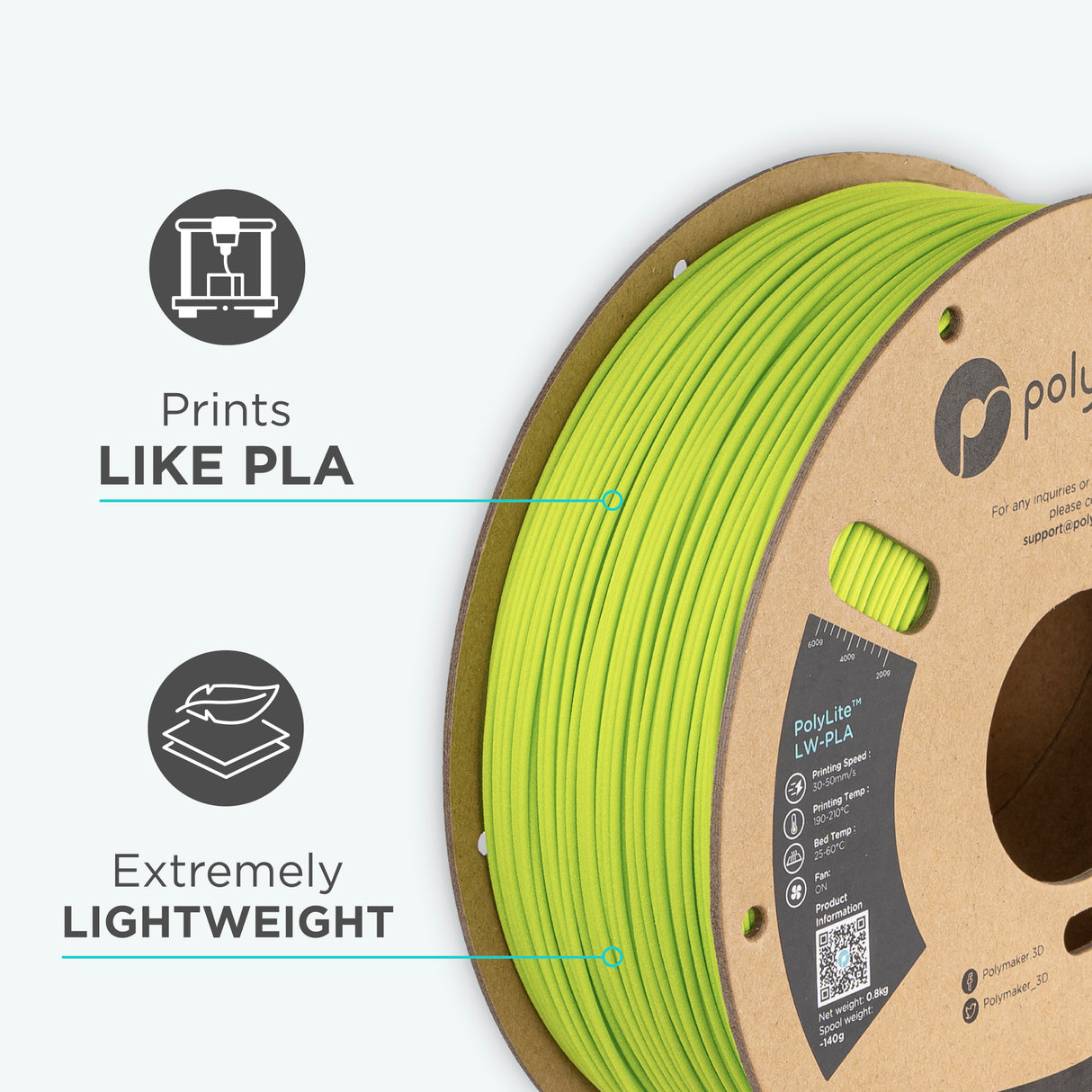

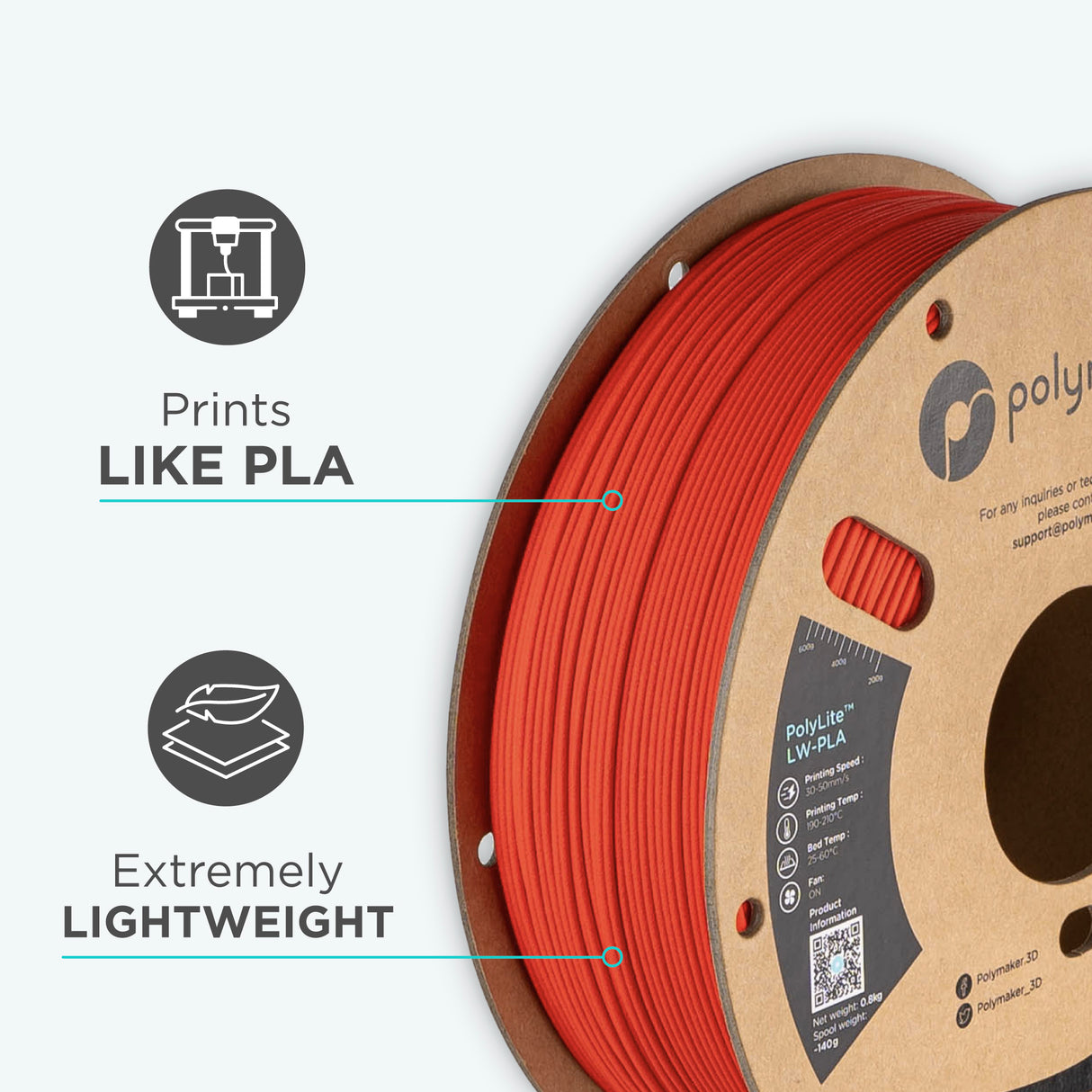

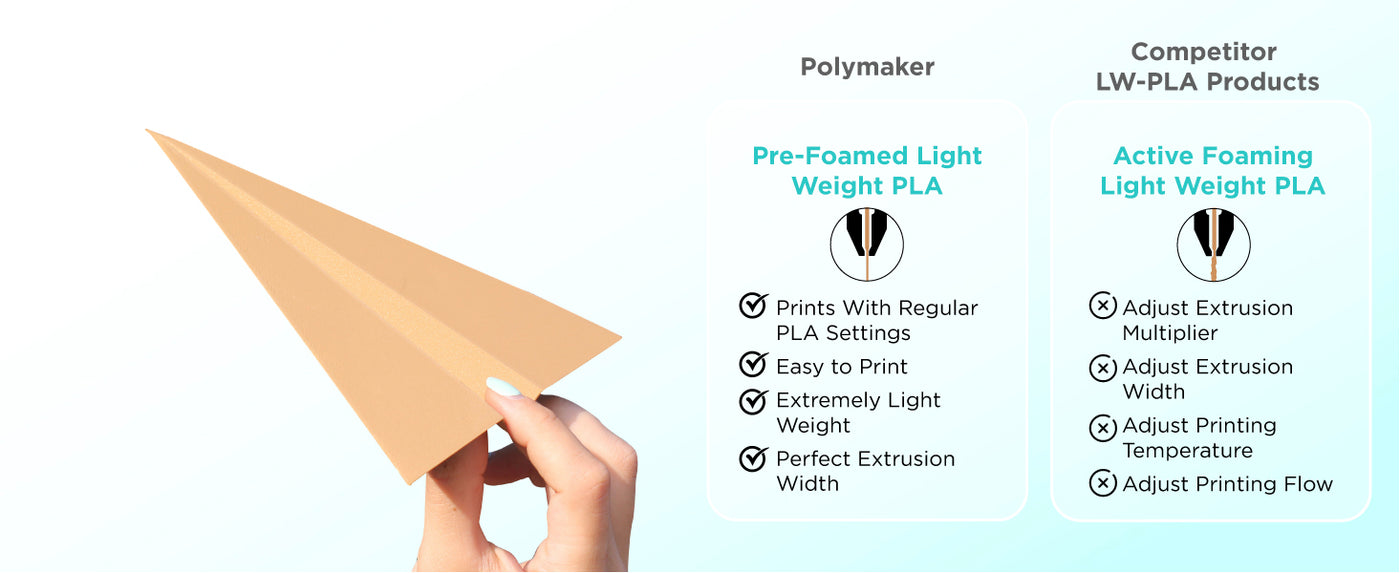

PolyLite™ LW-PLA is not an active foaming filament, which means it will not foam when extruded from the nozzle depending on the temperature. PolyLite™ LW-PLA is already pre-foamed.

What are the pros and cons between active and passive foaming?

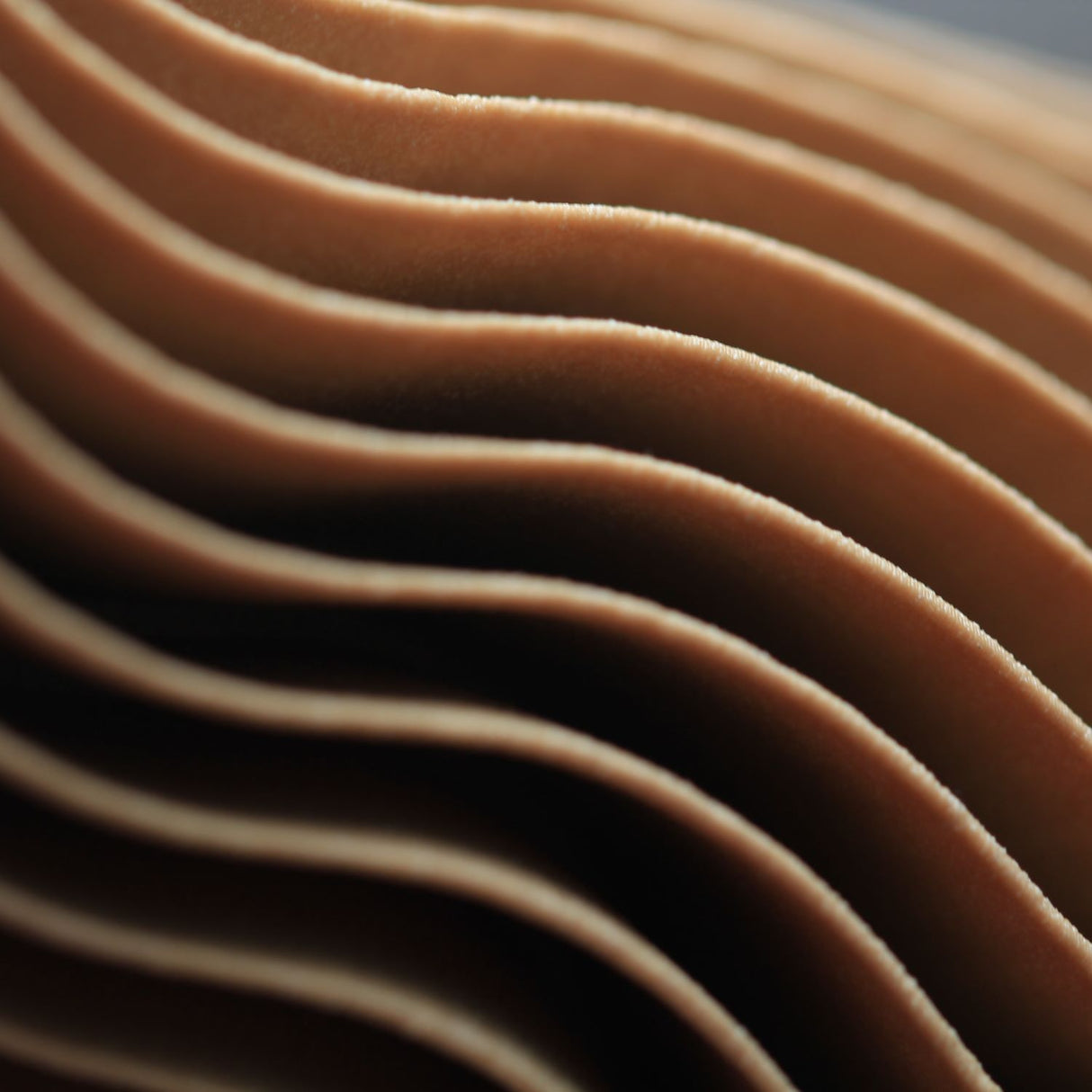

Active foaming:

You need to heavily modify your printing settings depending on the temperature and setup to compensate the foaming expansion of the material when printing.

You need to print at very high temperature to achieve light weight results (~250˚), these high temperatures will create a lot of defects on the print such as stringing and blobs.

At very high temperature, active foaming can achieve lighter print than passive foaming however the print may suffer of serious stringing defects.

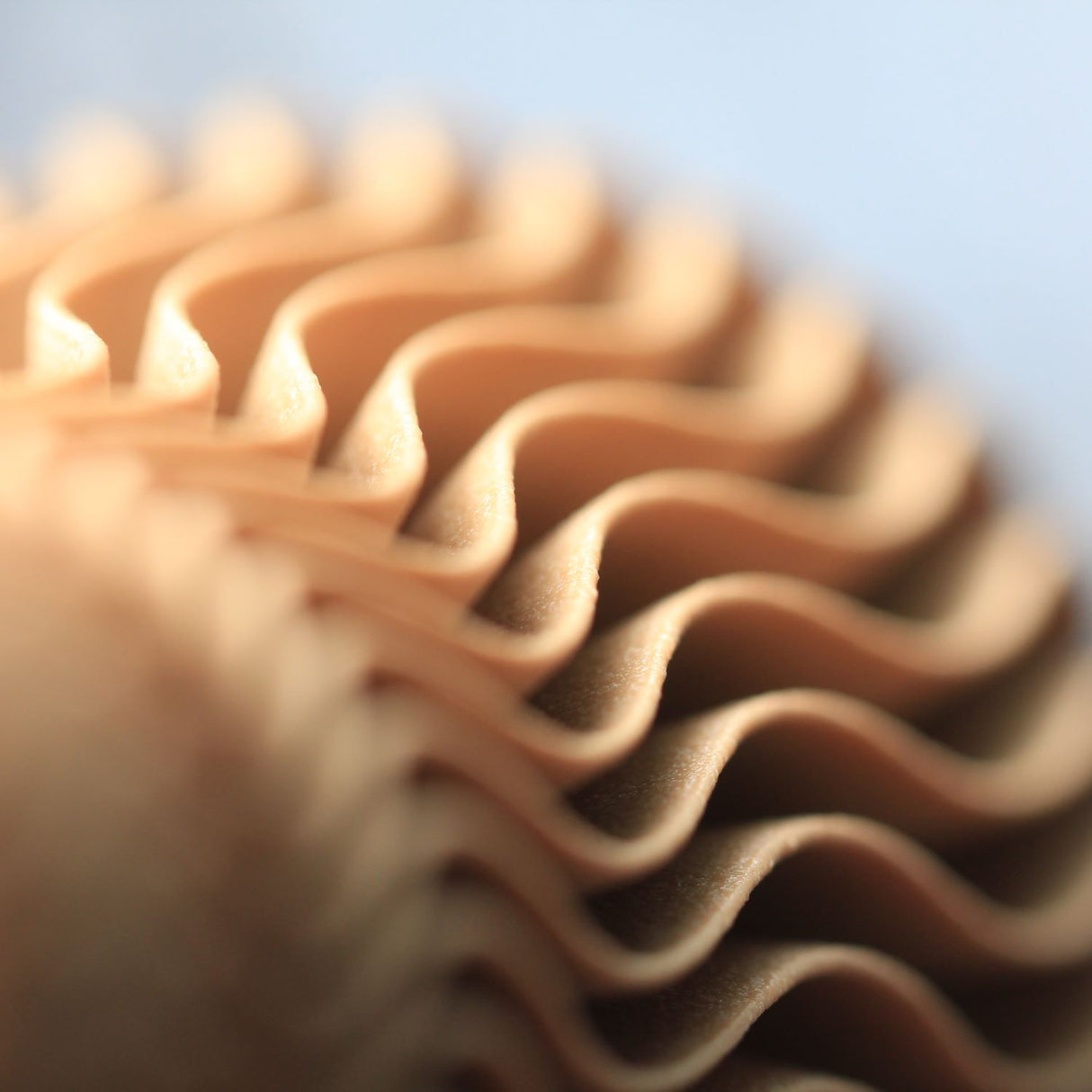

Passive foaming:

You do not need to change any settings from your regular PLA settings (slight increase retraction) as PolyLite™ LW-PLA will offer light weight results even when printing at very low temperature (~190˚C).

The lower the temperature the higher quality the print.

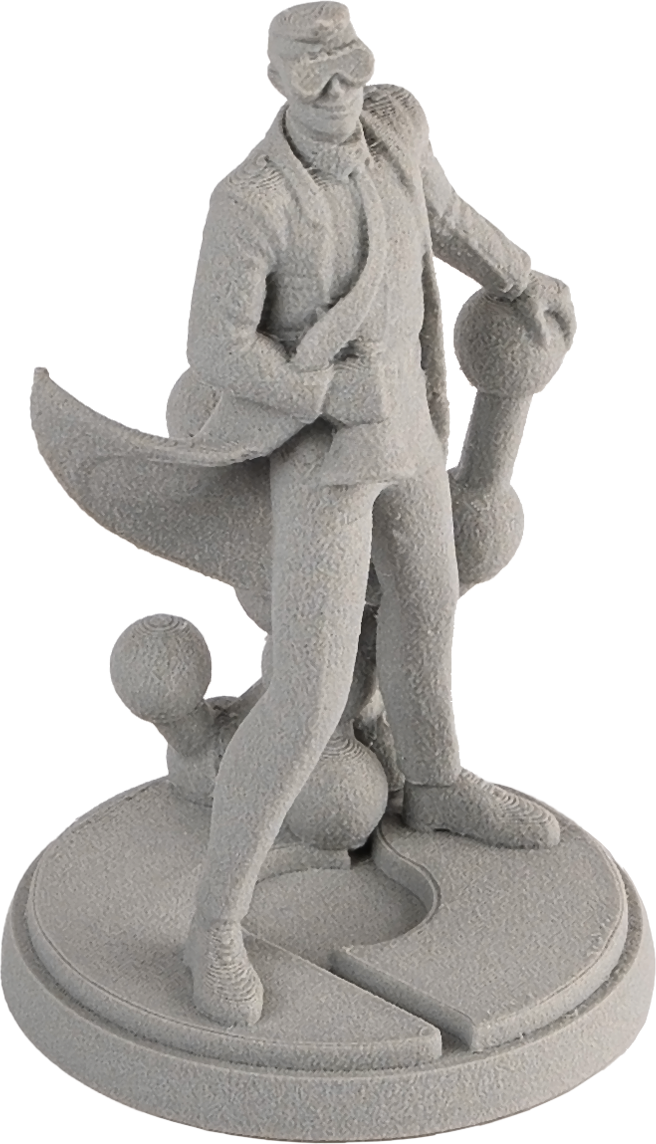

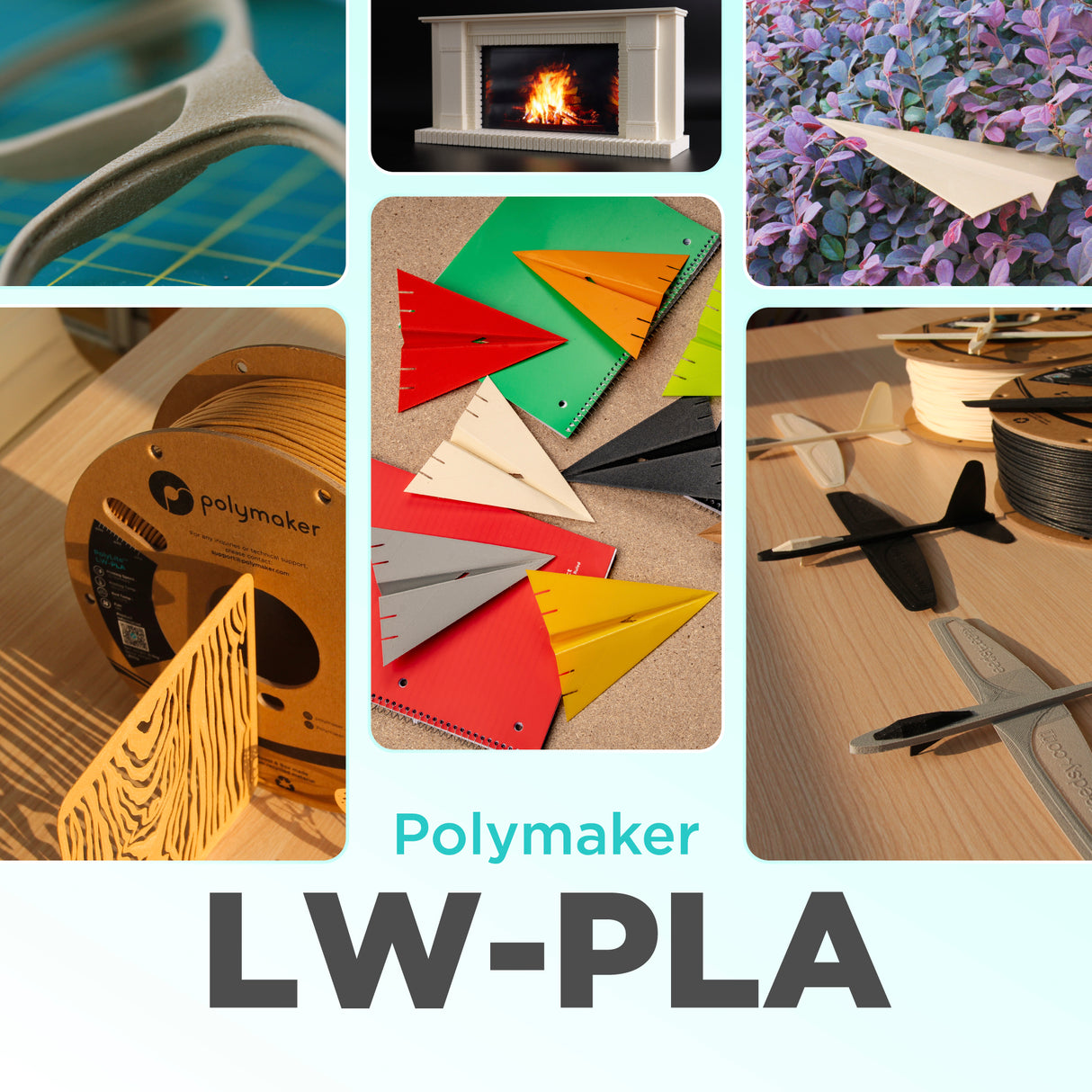

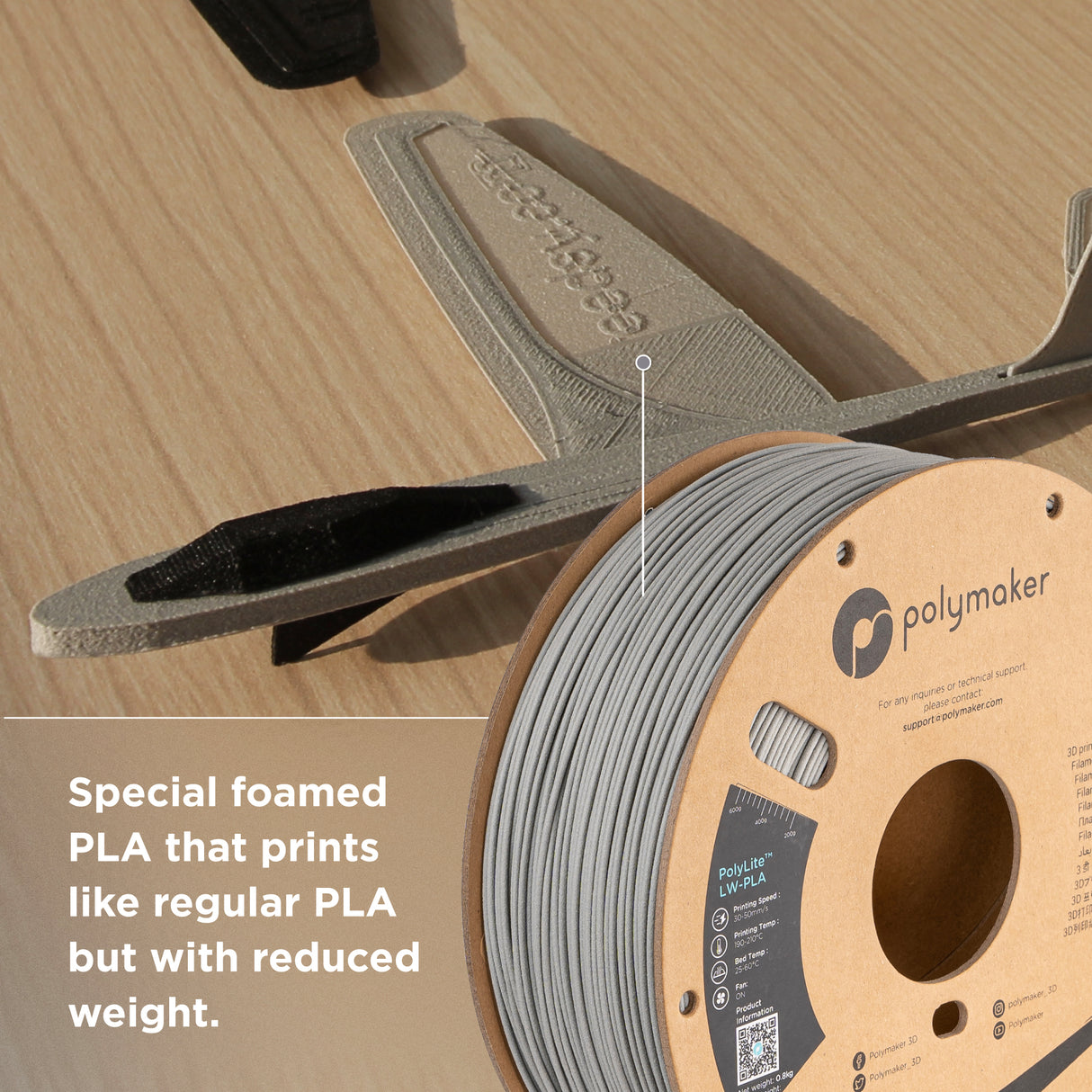

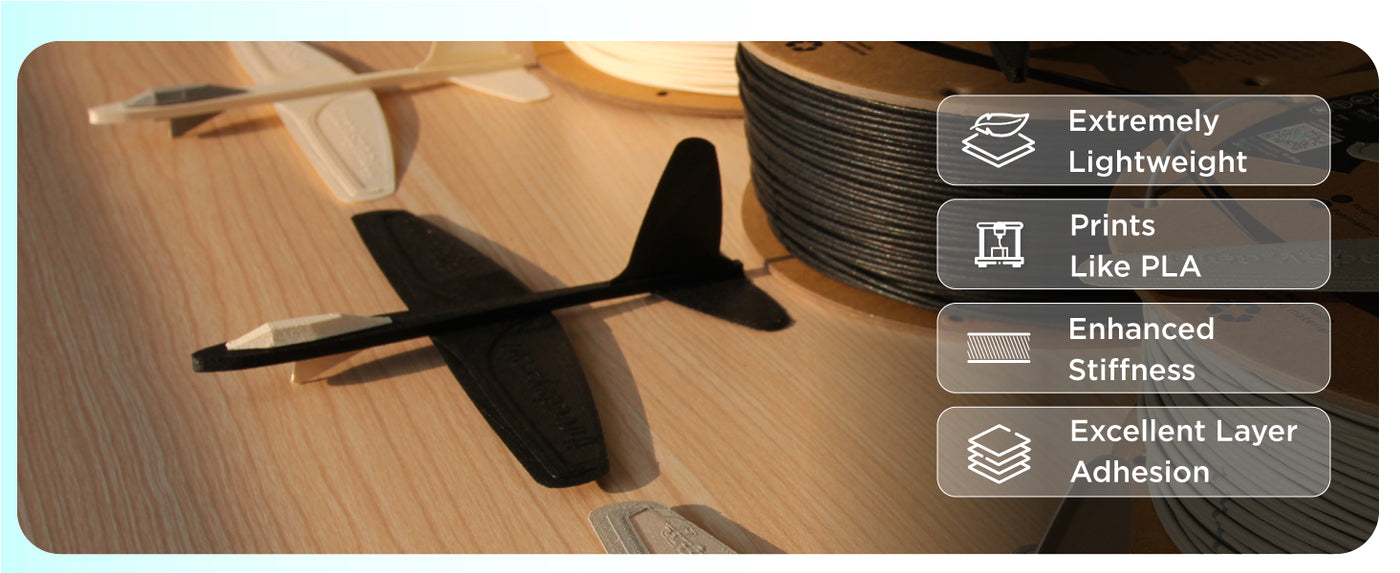

Is PolyLite™ LW-PLA good for RC Planes?

Yes, PolyLite™ LW-PLA is designed for ease of print and strong rigidity. For more information check out the review below about PolyLite™ LW-PLA for RC Plane application.

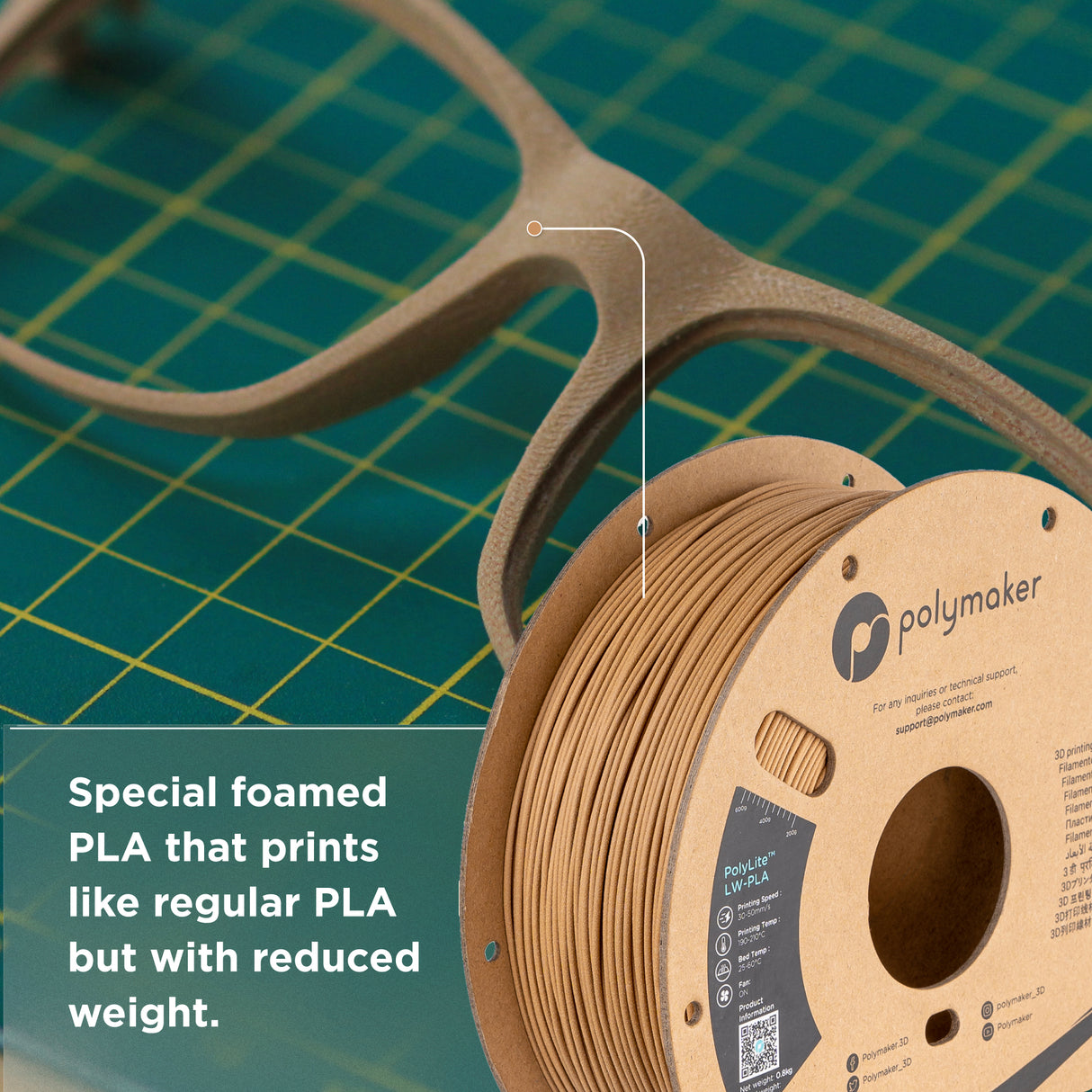

What is the difference between PolyLite™ LW-PLA and PolyWood™?

There is no difference! The wood color on LW-PLA is actually the same product as PolyWood™.

How do I reduce stringing?

LW-PLA and PolyWood™ are both materials that are prone to stringing. Here are some tips:

- 190˚C printing temperature (at 50mm/s printing speed)

- Maximum travel speed

- 0.5mm coasting and 1mm wiping (depending on the model)

Usually coasting and wiping is what helps the most

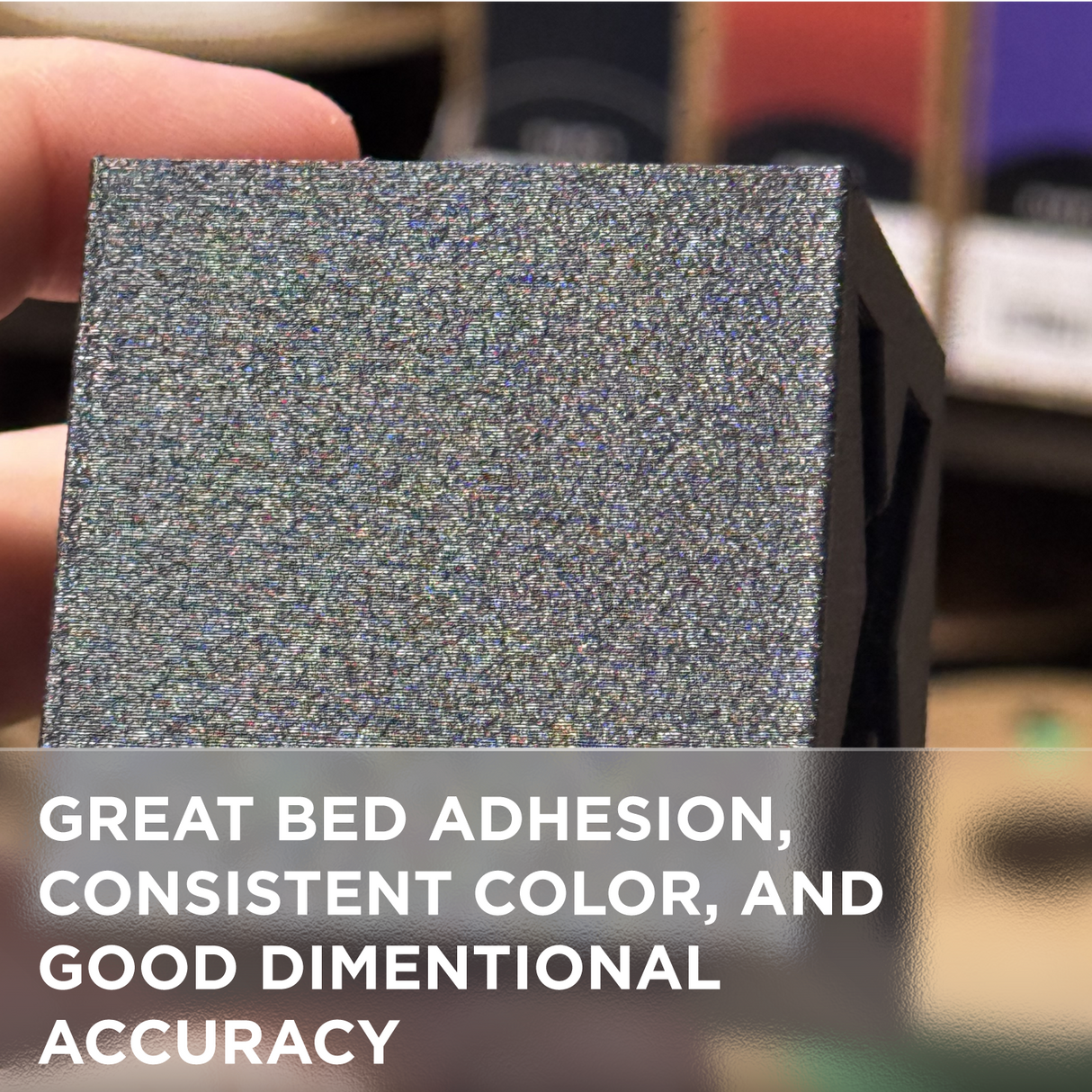

Will the spools work in an AMS?

Yes! We have redesigned the edges of our spools so all Polymaker products will now spin great in the AMS.

Is this material food safe?

Unfortunately we do not have any data whether this material is food safe. As of now, no 3D printing material on the market is FDA food safe compliant. This is because in order to be certified as food safe, the actual object needs to be certified and not the base material. The shape, bed used, environment the object was made, and much more goes into getting a food safety certificate. As of now there is no real certification that the FDA offers for 3D printing.

Do you sell refills?

We are sorry but we do not sell refills at this time

Is this material recyclable?

Unfortunately there is no great answer for recycling PLA at this time. Our cardboard spools are biodegradable but there is no great way to recycle PLA at this time.

Canada

Canada Global

Global