Elephant foot is an issue where the bottom few layers of your print are much thicker than the rest of your print. Almost as if the material was mushed out before correcting itself after a couple of layers.

This is a fairly straight forward issue to fix as there can only be a couple of causes.

Nozzle too close to build plate

When the first layer has the nozzle too close to the build plate, material is built up, smashed out, and presents itself as thicker than the dimensions of the actual part. Without enough distance between the nozzle and the build plate, this issue is going to be hard to avoid.

The elephant foot would course correct after about 5-10 layers, but the bottom section of your part will definitely be the incorrect dimensions.

Build plate too hot

Another reason this elephant foot failure can occur is from running your build plate too hot for the material being extruded. You should not print PLA with a build plate hotter than 60 degrees Celsius (sometimes only 50 degrees), but if you do, you can have a distorted bottom of your print.

This is because you are setting the build plate higher than the materials glass transition temperature. This means that the material on the bottom few layers becomes deformed as material is deposited on top of them. While it is easier to get good bed adhesion at these high bed temperatures, the deformation causes this elephant foot.

Make sure you are using the proper build plate temperature for the material you are using by referring to the manufacturer suggestions. If you know you have the proper Z-height and are operating within the suggested temperature range, and are still getting an elephant foot, you should attempt reducing your build plate temperature a bit further. Otherwise you can try out the next suggestion to make sure this problem is eliminated.

Use a raft

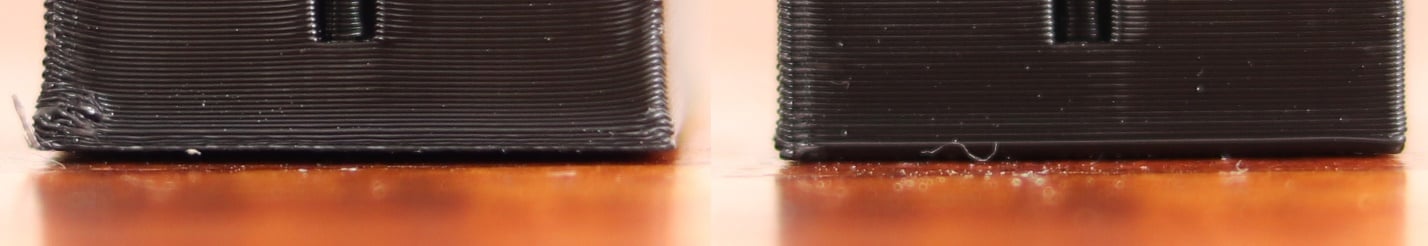

It is rare that we use a raft on my standard DIY machines, but if elephant foot is a consistent issue, a raft should make this failure disappear. A raft can cure having your nozzle too close to your build plate, and it can also fix having the build plate be too hot. This raft acts as a barrier between your print and the bed and should mean you no longer have any elephant foot issues. The photo above has before and after removing the raft on the same print, and below is this print with a raft (on the right) next to the version with the elephant foot issues (on the left).

Many printers are meant to use a raft standard in order to help with bed adhesion, and so long the settings are dialed in, a raft can be a great solution.

Negative initial layer horizontal expansion

This is a feature in Cura and may be called something different in other slicers. The initial layer horizontal expansion can cause the first layer to have a thicker or thinner expansion. Having a thick expansion can help with bed adhesion, but will increase your elephant foot issues. Setting this number negative can help to mitigate elephant foot on parts you are just having a ton of problems with.

We personally use a raft when this becomes an issue, but going this route should help as well.

Summary of Fixes and Precautions

• Make sure your nozzle is not too close to the build plate

• Confirm you are running your build plate within the suggested temperature range for the material used.

• Utilize a raft to mitigate the problem entirely.

Canada

Canada Global

Global