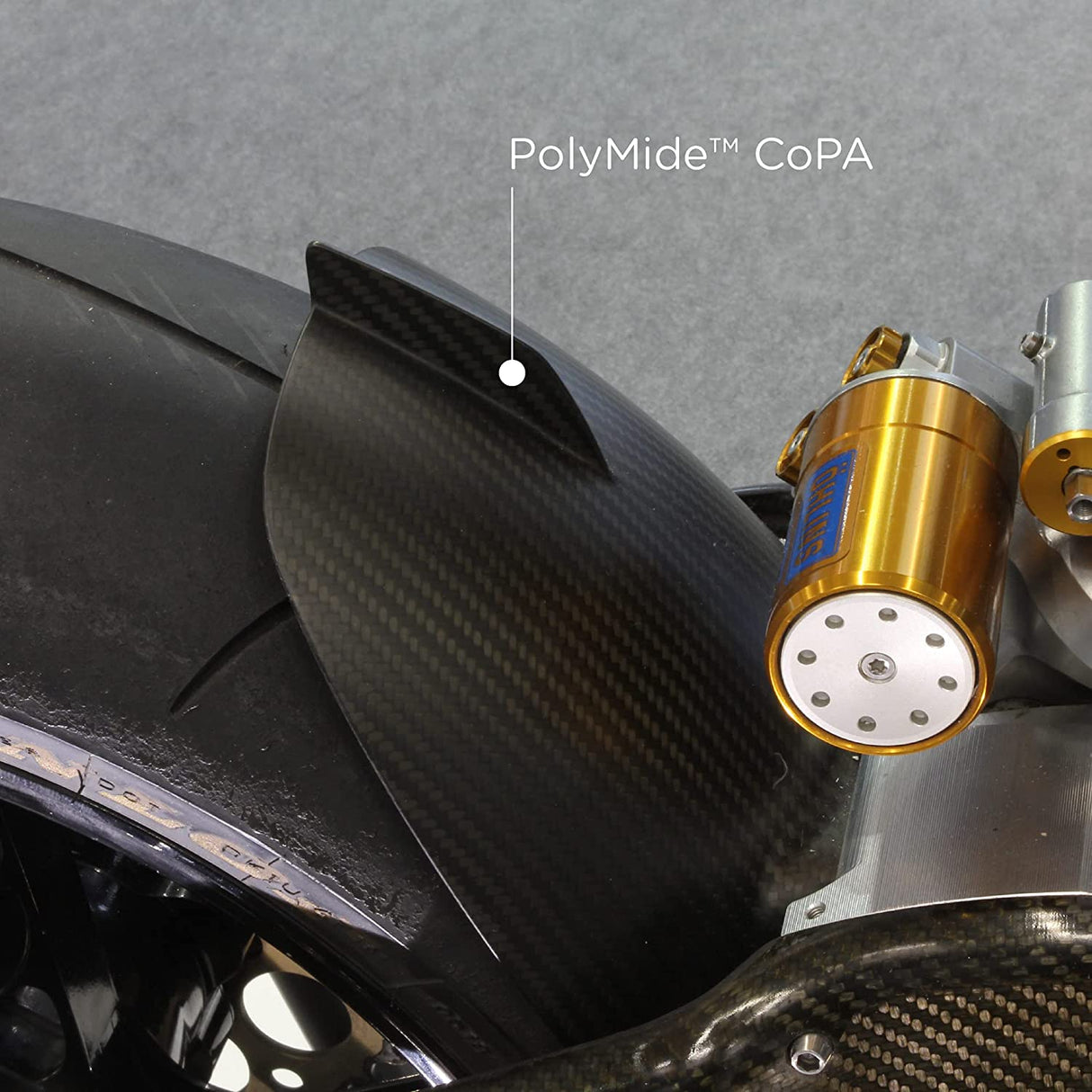

Does PolyMide™ CoPA requires an enclosed printer?

No, all our Nylon features our Warp-Free™ Technology which means it does not require a heated bed or heated chamber of more than 50˚C.

PolyMide™ CoPA can be printed on a 30-40˚C bed without enclosure.

Can I use PolySupport™ for PA12 with CoPA?

Unfortunately no - you cannot. PolySupport™ for PA12 was designed specifically for PA12 nylon and CoPA is a copolymer of Nylon 6 and Nylon 6,6.

We would suggest checking out PolyDissolve™ S1 (PVA).

Do you need to anneal PolyMide™ CoPA?

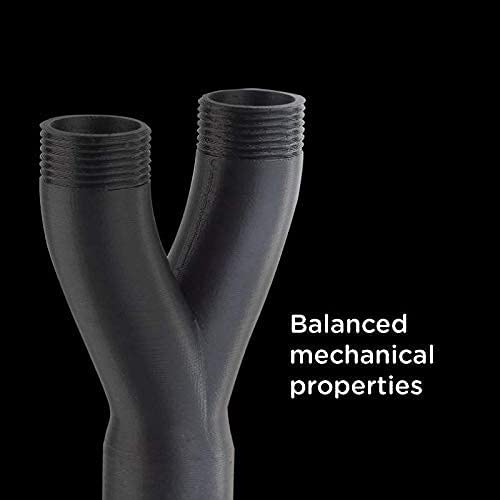

PolyMide™ CoPA displays outstanding mechanical and thermal properties when fully crystallized. The printed part will not reach full crystallization after the printing process, an additional step is required: Annealing.

You can anneal PolyMide™ CoPA by placing your part in the oven at 80˚C for 6h.

What is annealing?

You can find out more about annealing HERE

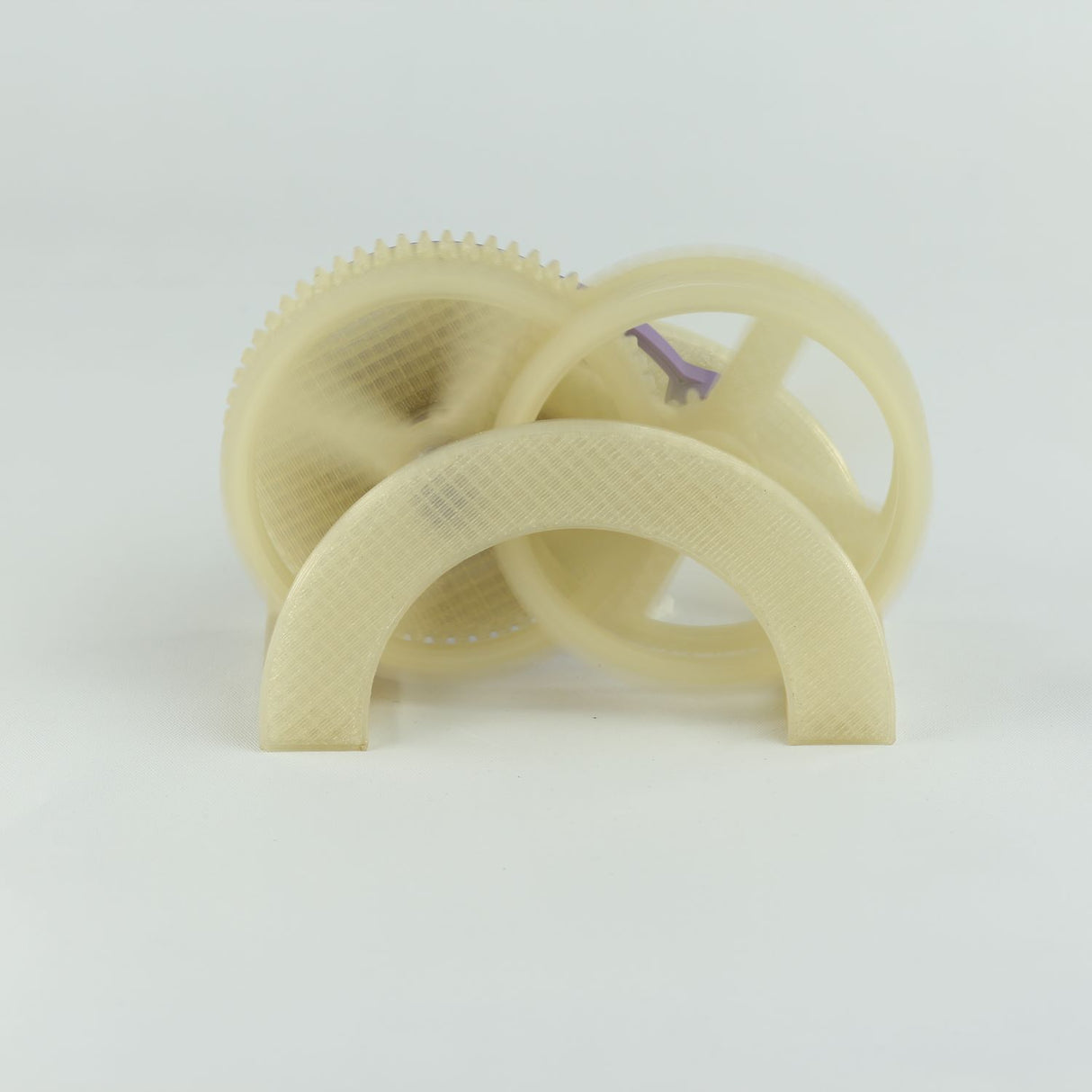

What is moisture conditioning?

Moisture conditioning refers to allowing the print to absorb moisture. This is inevitble since nylons are hygroscopic, but you can expedite the process by keeping the print in a high humidity climate, or submerging them in water, for 48 hours. All of our test specimens were annealed at 100˚C for 16 hours, and then immerged in water at 60˚C for 48 hours. The average moisture content of specimens is 2.57%.

Should I anneal before or after moisture conditioning?

When you anneal in a convection oven, you will dry the part out. So if you moisture condition before annealing - you will need to moisture condition again after. So we would suggest to moisture condition after annealing.

Why do you use such a low build plate temperature with your nylons?

Our nylons come with our Warp-Free™ Technology. In order for this Warp-Free™ technology to work as it should - we want to make sure the build plate and the ambient air temperatures are both below 50˚C. We then anneal the print after to get it's full strength.

Learn more HERE

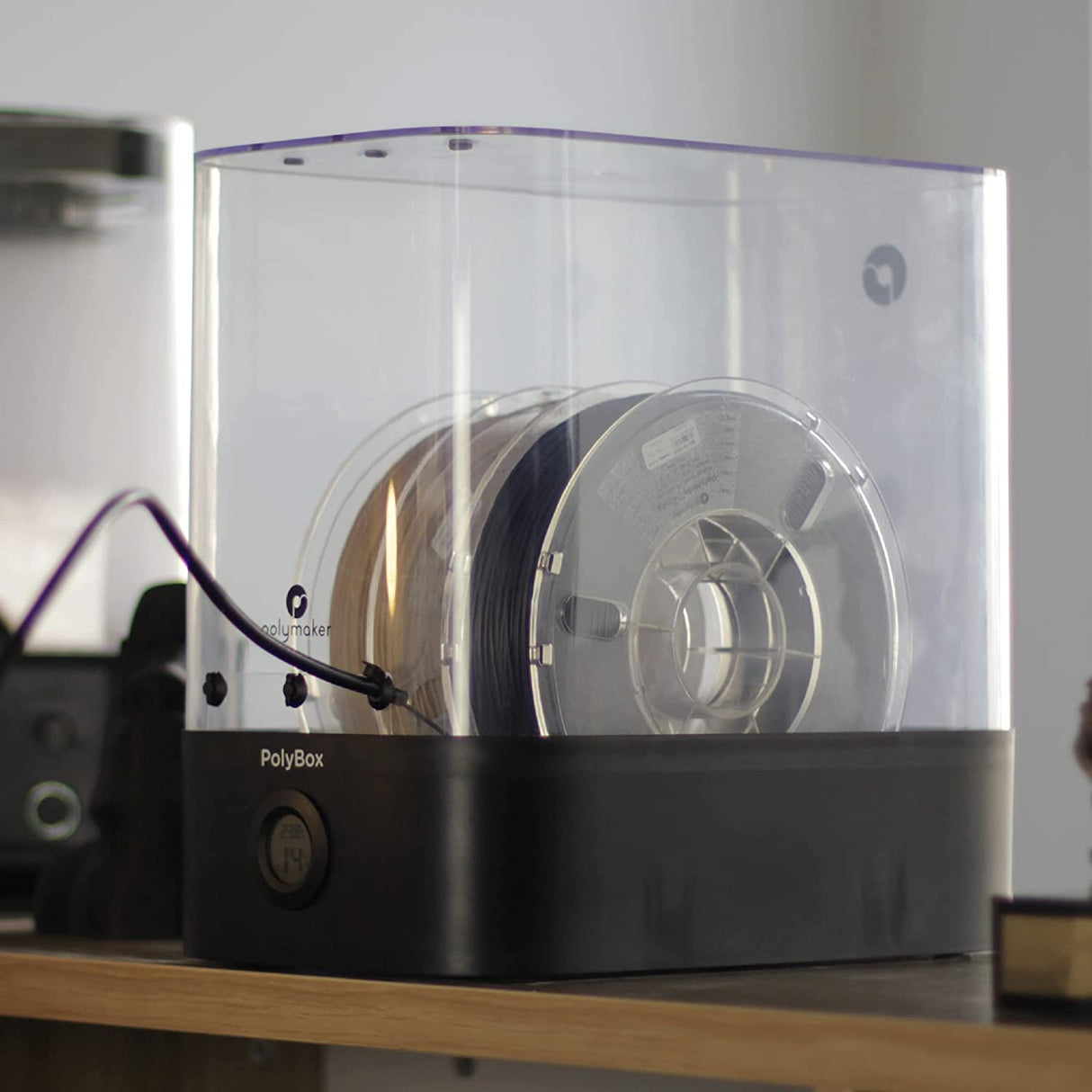

Will the spools work in an AMS?

Yes! We have redesigned the edges of our spools so all Polymaker products will now spin great in the AMS.

What is the shrinkage rate of PolyMide™ CoPA?

The shrinkage rate depends on the print model size and infill setting.

Canada

Canada Global

Global