Now that we have more material science knowledge it will be easier to understand the different technologies that Polymaker is using in our products to help combat some of these material limitations:

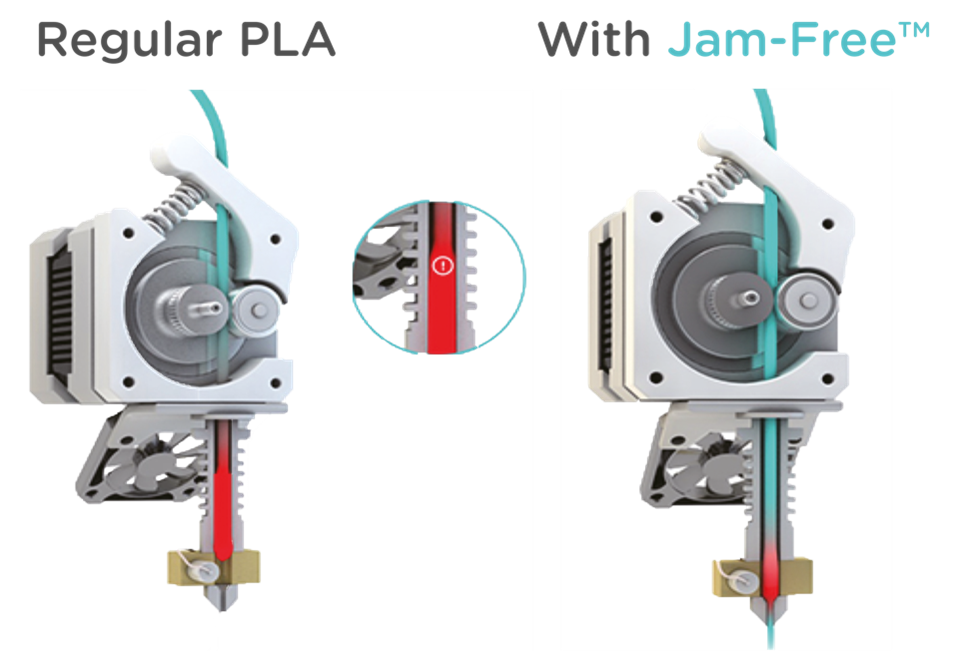

Jam-Free™ Technology:

To understand this technology, let us understand the main root cause of jamming issue:

The print head is divided in two main parts: the hot end and the cold end. The hot end is where the heat block will heat up and melt the filament, the cold end will prevent the heat from the hot end to disperse and damage other components or soften/melt the filament before it needs to be.

However during long prints, dual extrusion prints and simply with a badly design heat sink the heat will climb up to the cold end and soften the filament which can lead to filament expansion thus jam, or the extruder chewing the filament.

PLA is the most concerned by this issue because it has a very low Tg (~60˚C) so if the temperature raised a little bit over 50˚C, it can already create a risk of jam. 2.85mm filament is less concerned by this issue because they are thick enough to stay more rigid than 1.75mm.

To solve this issue, Polymaker increases the heat resistance temperature of their 1.75mm PLA based product to 140˚C.

Since PLA is a semi-crystalline polymer, Polymaker is able to do this by annealing the filament first, which will increase the crystallinity degree of the filament. As we explained earlier, the crystal will start to break at Tm (~150˚C for Polymaker PLA) so it provides more heat resistance to the material.

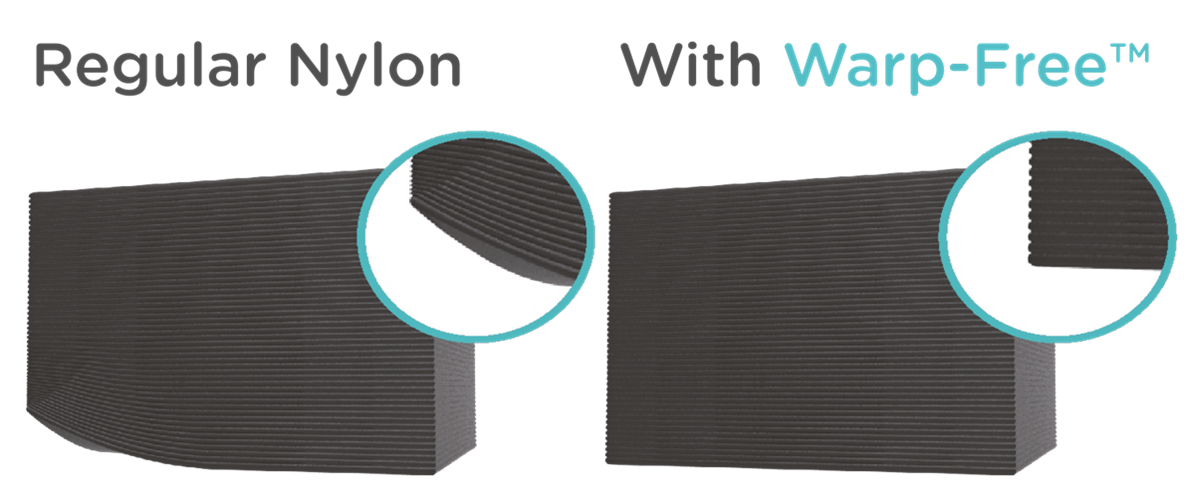

Warp-Free™ Technology:

This technology is used by Polymaker in their PolyMide™ family (Nylon based material). We already learned a lot about warping issues and potential root cause on our Material Science page. This technology solves one of the root cause of warping issues: Crystalization.

Indeed, Nylon is known as challenging to print because of its warping behavior, because when printing, the quick formation of crystals within each layers will create a lot of internal stress - resulting in part deformation.

Polymaker’s technology is not only reducing this stress, but it is increasing the mechanical properties of the part. The technology slows down the crystallization rate of the polymer, which prevents it from quickly forming small crystals within each layer as they are printed. Instead, it allows the polymer to slowly build big crystal across layers, since multiple layers have time to be printed before the formation of crystals. These crystals across the layers will also significantly increase the inter layer adhesion. This is also the reason why Polymaker will recommend to anneal the part after the printing process. Annealing ensures the part has reached its highest degree of crystallinity, providing the best thermal and mechanical properties.

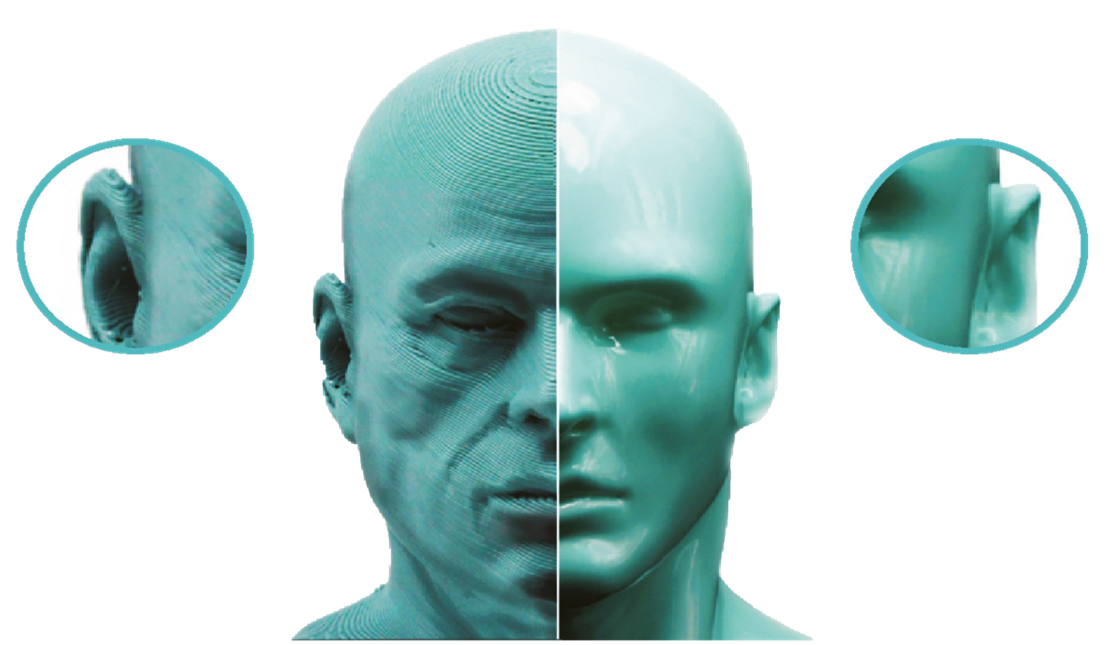

Layer-Free™ Technology:

This technology involves less of polymer science but more a perfect combination of the right material with the right solvent. Polymaker was interested in the smooth results that an acetone bath could give to an ABS print, however they thought that the ABS was too difficult to print, and the acetone could be a dangerous chemical and not safe to use. And there were no actual devices which were designed for the purpose of using this solvent to polish an ABS part.

The first challenge for Polymaker was to find a polymer which could be easy to print and also react with a solvent which could be sourced easily and less dangerous than acetone.

Polymaker finally found PVB as the perfect candidate. From there they started to develop specific material formulas PVB based and PolySmooth™ was the results of this development.

PolySmooth™ could be printed with the same settings as PLA and could then be smoothed with alcohol.

The second challenge was to design a device which could safely and reliably polish a PolySmooth™ model using alcohol. The Polysher™ was the result of this device development. The core of the Polysher™ being the nebulizer, the carefully chosen membrane and the specific algorithm developed to find the right frequency for the nebulizer.

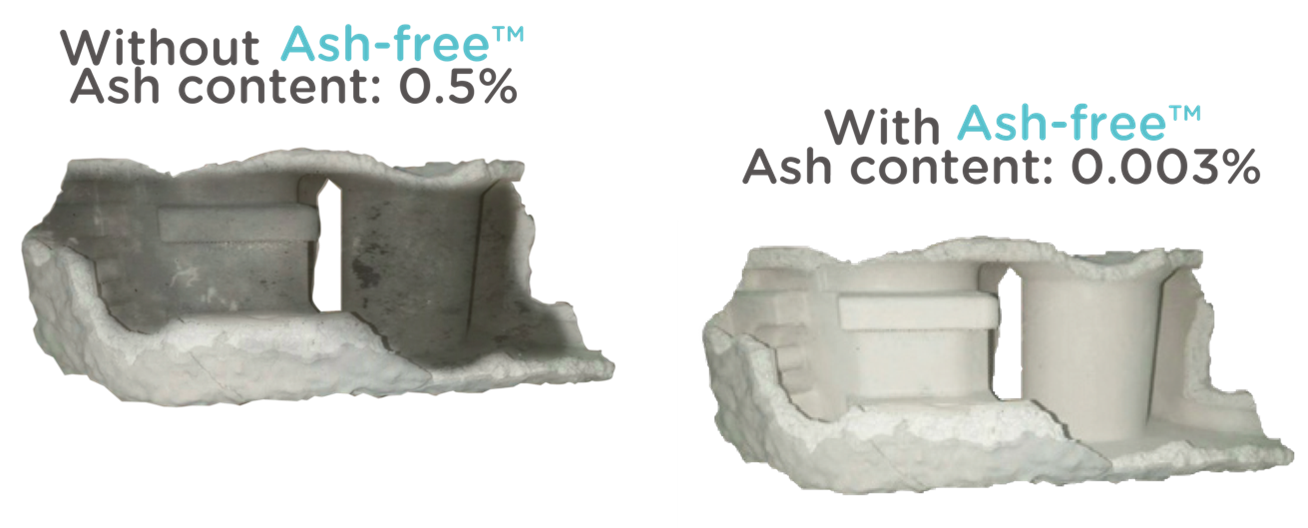

Ash-Free™ Technology:

This technology is used in Polymaker Polycast™. It uses a specific combination of different precisely chosen components to create a material for casting. These components are carefully chosen to burnout without any residues.

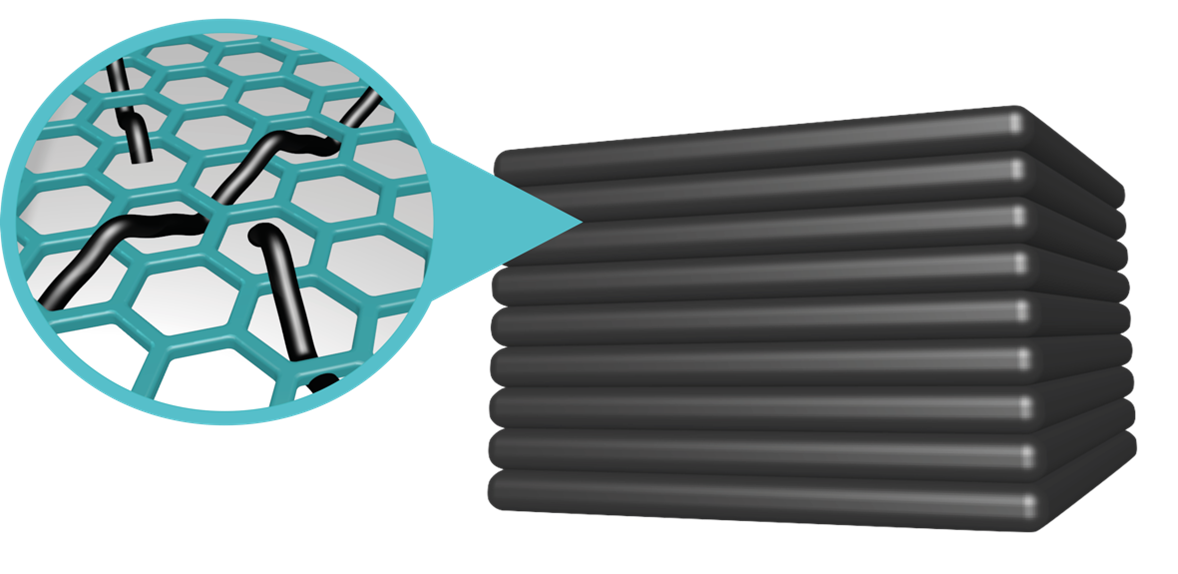

Fiber Adhesion™ Technology:

Fiber reinforced materials provide excellent thermal and mechanical properties, however in extrusion based 3D printing, it can negatively affect the layer adhesion. Polymaker believes that the layer adhesion issues come from the fibers not bonding/matching well with the matrix polymer.

After months of development, they successfully optimized the surface chemistry of the fibers to achieve better dispersion and bonding to the matrix.

When implementing this technology to PolyMide™ PA6-CF and PolyMide™ PA6-GF, the layer adhesion was not negatively affected, but actually stronger (+27% for CF, +15% for GF).

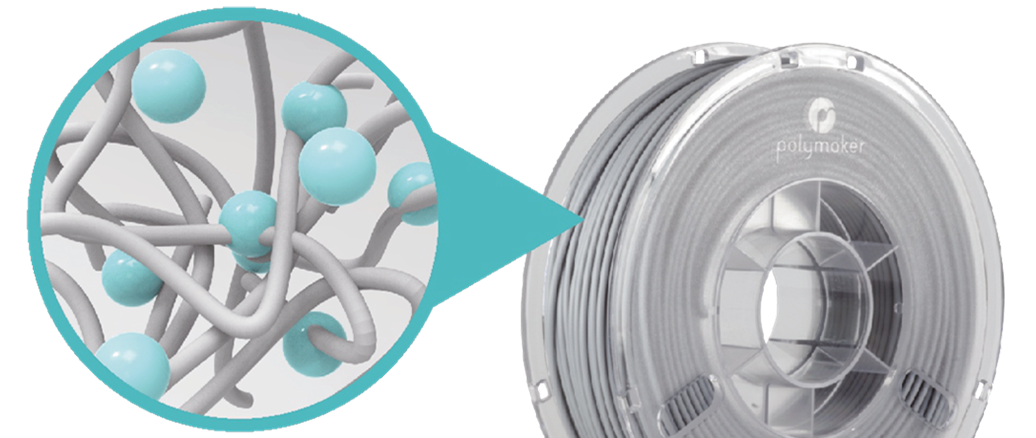

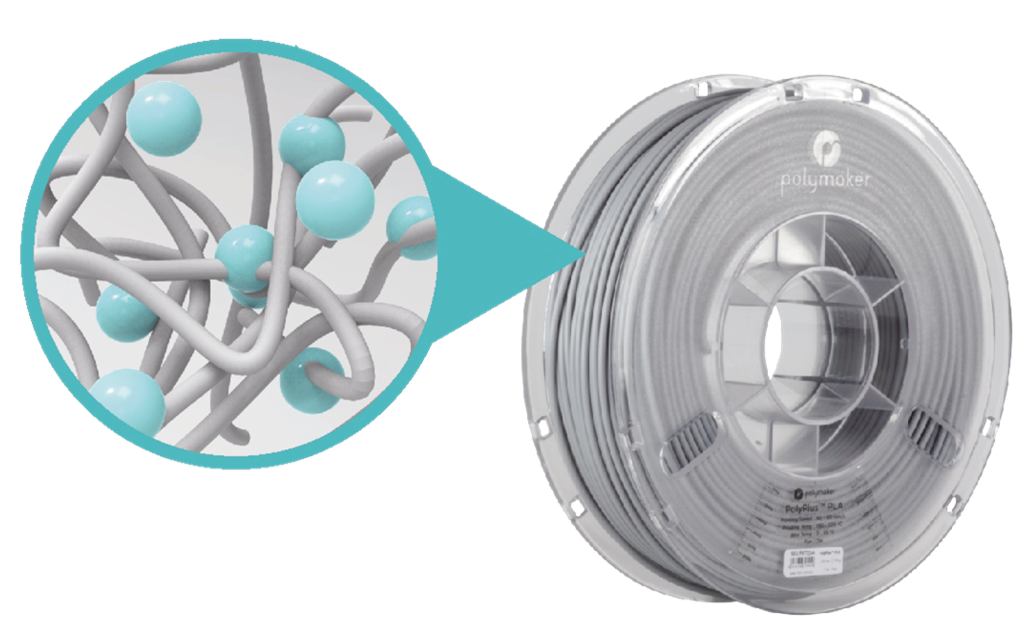

Nano-reinforcement Technology:

This technology is used in Polymaker’s PolyMax™ family of products. It reinforces the polymer with nano-particles that make it much tougher, while simultaneously keeping similar printing conditions. PolyMax™ PLA, PolyMax™ PETG and PolyMax™ PC are the 3 products from the PolyMax™ family. They all print with the same settings as their regular counterpart: PolyLite™ PLA, PolyLite™ PETG and PolyLite™ PC, however they can achieve up to 5 times the toughness, making them more durable. As reviewed earlier in this page, the fracture toughness can be well represented by the impact resistance of the material.

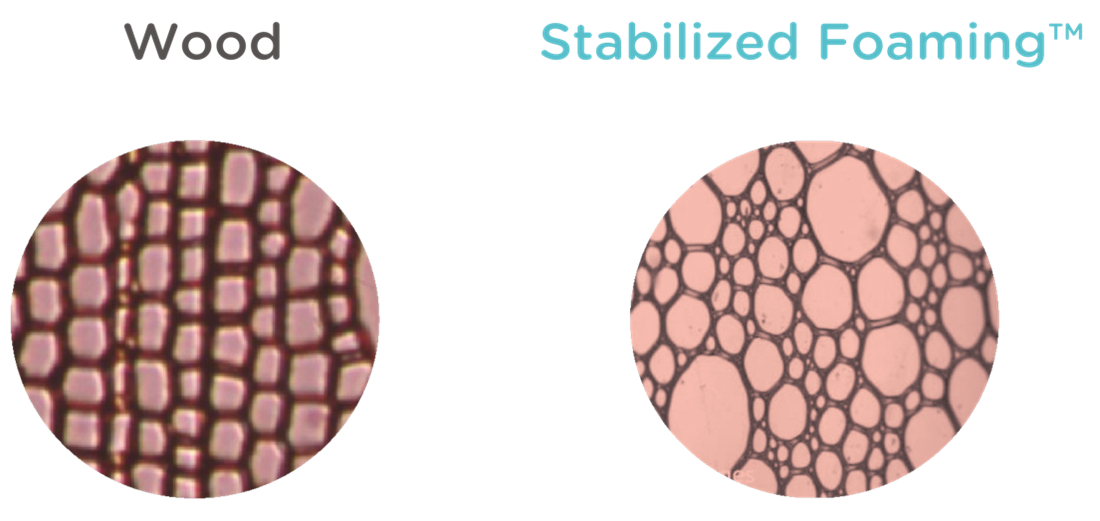

Stabilized Foaming™ Technology:

This last technology is one of the earliest developments by Polymaker. After several bad experiences clogging nozzles with printing wood filled filament, they thought about ways which could make a filament look like wood without actual wood powder in it, since wood powder in the filament could negatively affect the printing process.

Polymaker realized that the main reason for the appearance of wood was its plant cell structure and color. It was easy to copy the color of a certain wood, and the plant cell structure was copied using a foaming agent, creating a similar cell network.

The main challenge was to design and formulate a foam structure which would not be negatively affected by the extrusion process of the 3D printer, thus the “stabilized” in “Stabilized Foaming”, meaning that the foam will remain stable after the printing process.

Canada

Canada Global

Global